We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

MakerBot METHOD X 3D Printer

manufacturer No -900-0002A

Get Started Prototyping on METHOD X with 1 FREE Spool of ABS-R

with Promo Code FREEABSR at Checkout

INDUSTRIAL 3D PRINTING MADE ACCESSIBLE

Print manufacturing tools and production parts to spec with real manufacturing grade materials

TWICE THE STRENGTH. TWICE THE ACCURACY.

Patented VECT™ 110 (Variable Environmental Controlled Temperature) Thermal Regulation evenly heats and controls the print environment leading to parts that are 2x stronger on the z-axis, and 2x more accurate across the board.

Print continuously for hours, days, or weeks, thanks to METHOD’s unmatched industrial build quality.

METALS, COMPOSITES, AND POLYMERS PRINT BETTER ON METHOD X.

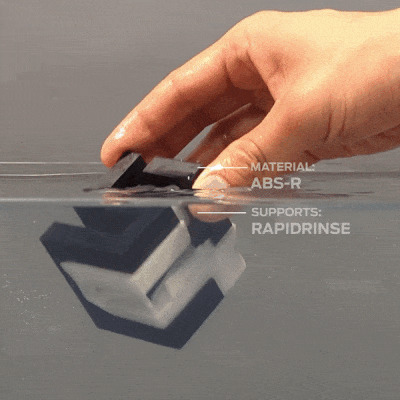

Print real ABS parts with RapidRinse™ supports that dissolve faster than anything else

15 patented features allow for better environmental controls than on any other desktop 3D printer.

Go from 25+ tuned materials to infinite 3rd party options with the LABS GEN 2 Experimental Extruder.

6-in-1 Modular Performance Extruders allow for quick change between material groups, preventing cross-contamination.

INDUSTRIAL POWER WITH DESKTOP EASE.

CloudPrint™ gives you and your team secure access to 3D print from anywhere.

CloudPrint™ natively accepts the most popular CAD file types.

5” capacitive touchscreen provides an intuitive step-by-step setup and real-time controls on your jobs.

Auto-Calibration takes the guesswork out of setup and ensures a level build plate and extruder-alignment.

SmartAssist Material Loading makes material changing a breeze from material bay to extruder, hands-free.

360° OF 110°C

CIRCULATING HEATED CHAMBER

Many desktop 3D printers use heated build plates to try and regulate their environment and prevent warping on the print bed. This improves adhesion to the build plate for the first layer and… that’s about it. METHOD uses the patented Circulating Heated Chamber to rapidly warm the entire build chamber up to 110°C providing optimal print conditions from first layer to last. The result is a degree of dimensional accuracy typically reserved for industrial 3D printers (±0.007 in), at the base layer and everywhere else.

AUTOLOADING FOR QUICK MATERIAL CHANGE

SMART ASSIST MATERIAL LOADING

Material loading on 3D printers can be a pain. METHOD’s material loading system is designed to take complexity and frustration out of the equation. Just drop the Smart Spool into the Dry Sealed Material Bays located on the front of the printer, and feed the filament tip into the slot, close the drawer and the printer loads the filament all the way up and into the extruders so that it’s ready to print.

PRECISION LEVELED WITH QUICK PART RELEASE

MAGNETIC SPRING STEEL BUILD PLATE ON MACHINED ALUMINUM BASE

The build surface is another crucial element in FDM 3D printing. Whether you’re printing in ABS, Nylon, or just PLA, an uneven surface can lead to a warped print. METHOD combines two elements to create a unique solution. First is an aluminum base plate, machined and factory-calibrated for extreme flatness. Second is a spring steel build plate that magnetically conforms to the base plate via a dozen high-strength magnets. This not only provides flatness, but also makes print removal a breeze. Just pick up the build plate and flex it to pop the print off.

TWO TOOLHEADS. INFINITE POSSIBILITIES.

DUAL PERFORMANCE EXTRUDERS

When it comes to FDM 3D printing, the toolhead or extruder is one of the most important features. Based on an industrial-grade design from Stratasys, METHOD’s extruder was designed from the ground up with the professional in mind. With an all new lengthened thermal core, dual drive gears with 19:1 gear ratio of torque, and MakerBot’s industry-leading intelligent sensor suite, METHOD comes with significantly improved print quality and speed.

ABS, FINALLY AS EASY AS PLA

With our proprietary RapidRinse™ support, achieve incomparable ABS parts with unprecedented ease.

TAP WATER SOLUBLE

Forget the cumbersome wash tanks and chemicals, RapidRinse™ dissolves in pure tap water so it’s easy to use in just about any environment

DISSOLVES IN MINUTES*

You don’t have time to wait around while your print dissolves, so we’ve engineered RapidRinse™ to dissolve faster than PVA and competitive high-temp dissolvable support materials.

*Dissolution time may vary based on part geometry and dissolution methodology.

ALL THE RESOURCES YOU NEED TO START 3D PRINTING OUT OF THE BOX

We’ll send onboarding instructions, tips, and videos to get you started printing reliable parts straight out of the box with METHOD.

With over 25 videos and over 100 articles, our team has all the content you need to keep printing high quality parts in a variety of materials on METHOD.

Whether you prefer phone, email, or live chat, MakerBot support experts are just a step away.

TECH SPECS

HEATED CHAMBER TEMPERATURE:

110° C Maximum Temperature.

BUILD VOLUME:

Dual extrusion: 15.2 L x 19 W x 19.6 H cm / 6.0 x 7.5 x 7.75 in

Single extrusion: 19 L x 19 W x 19.6 H cm / 7.5 x 7.5 x 7.75 in

OVERALL DIMENSIONS

41.3 L x 43.7 w x 64.9 H cm.

FEATURES

Dual performance extruders.

Dry-sealed material bays.

100°C circulated heated build chamber.

Wifi Connectivity and 21 on-board sensors.

Remote monitoring and printing.

25 Compatible CAD file types.

5" Full-color capacitive touch screen.

Over 300,000 hours of reliability testing.

WHAT'S INCLUDED

1 MakerBot METHOD X 3D Printer.

1 Spring Steel Build Plate.

1 Model 1XA Performance Extruder (Version 1).

1 Support 2XA Performance Extruder (Version 1).

1 Nozzle Brush.

1 Hex Key.

1 USB A-to-B Cable.

1 US Power Cord.

1 EU Power Cord.

| Brand Name | MakerBot |

|---|---|

| Model Number | 900-0002A |

Customer Reviews

of customers recommend this product